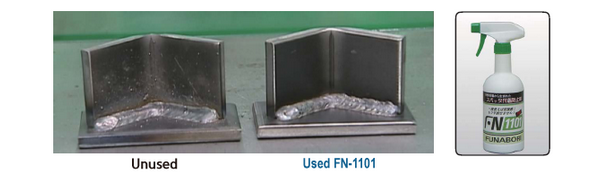

Anti-weld spatter agent FN-1101

You will realize the amazing effect from the moment you use it.

This is an innovative and exclusive anti-weld spatter agent.

This product can be used for mild steel, stainless steel, and bonded steel sheets.

Available in a large economy container size of 18 liters.

(Corresponding to the net amount contained in 85 pressurized cans )

- We accept orders for a minimum quantity of six pressurized cans (420 ml each).

- We accept orders for a minimum quantity of six spray bottles (500 ml each).

Instructions for use

- Move the FN-1101 agent from the container to the sprayer.

- Adjust the nozzle of the sprayer so that the agent is sprayed in a form of a mist.

- Spray a small amount of the FN-1101 anti-spatter agent in the sprayer on the area that will be welded.

(* Pay attention not to spray too much of the FN-1101 agent.)

* The data shown above is based on actual results during use.

[Precautions for use]

* Limit the number of layers to only one in thick-plate welding. For two/three layers, the agent will be less effective.

* In the case of high-current welding, use the current value of about 350 A as a guide.

* If the agent gets in your eyes, flush the eyes thoroughly with water.

* If the agent gets on your hands, wash the hands thoroughly with soapy water.

* The net contents of a pressurized can show the amounts of both the agent and gas.

* For more precautions, see the attached documents.

Exclusive anti-spatter agent for nozzles FN-2813

You will realize the amazing effect from the moment you use it.

This is an innovative and exclusive anti-spatter agent for nozzles.

Instructions for use

1.After welding, thoroughly wipe the dirt off the disconnected nozzle.

2.Soak the nozzle in the FN-2813 agent for several seconds.

3.Let the nozzle dry naturally.

The nozzle looks hardly changed after use. If spatters adhere to the nozzle,

they can be removed easily simply by wiping the nozzle.

Rap the nozzle and the spatters come off easily.

*The data shown above is based on our actual results of use. * One bottle lasts for about three months when this agent is used for five nozzles per day. (Caution) * When using the FN-2813 agent, make sure to scrape the nozzle part with an accompanying Scotch Brite pad every time before use. * If dirt is found on the area where the FN-2813 agent has been applied, remove it with a Scotch Brite pad. * The effect will last for about a whole day with one application a day. (Note: When using high-current/continuous robot welding, set the effective period to approximately half a day as a guide.) * When using a new nozzle, make sure to scrape the area of the nozzle to be soaked with an accompanying Scotch Brite pad before use. * When using a new nozzle, repeat the processes of application/drying of the agent to the nozzle three times before use. (On and after the second time of using the nozzle, only one time of this process is enough.) * If this agent contacts your eyes or hands, rinse the eyes or hands thoroughly with water. If conditions do not improve, consult a doctor.